What is Cyanoacrylate?

In its simplest form, cyanoacrylate can be thought of as super glue — a quick-drying, strong-bonding clear adhesive. It takes the shape of a polymer (plastic) resin in its cured form and a monomer in its uncured form. You’ve likely come across the trademarked adhesive known as Super Glue, which you may not have realized is also, cyanoacrylate, it’s generic name.

However, there is far more to this adhesive than just super glue. The cyanoacrylate family of glues includes fast-drying, strong-bonding, one-part adhesives that have an industrial, household and even medical applications. The following questions and answers should hopefully tell you all you need to know about cyanoacrylate, uses, differences, techniques and more.

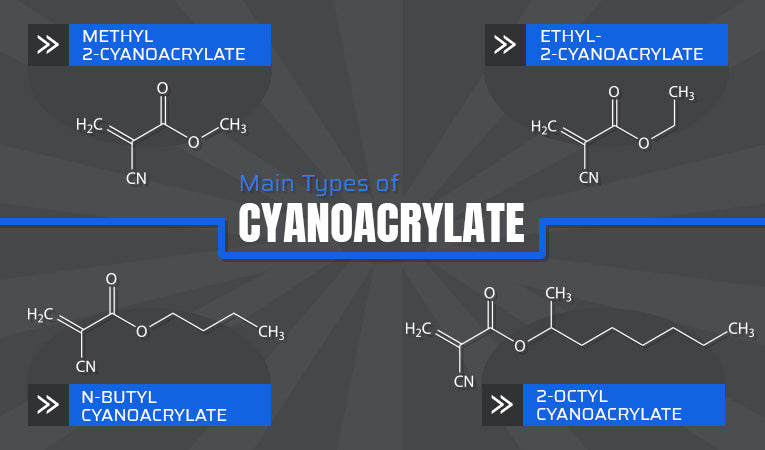

What types of cyanoacrylate are there?

The main types of cyanoacrylate are methyl 2-cyanoacrylate, ethyl-2-cyanoacrylate, referred to by the generic term superglue, and n-butyl cyanoacrylate and 2-octyl cyanoacrylate, which are both used in medical applications.

How does the cyanoacrylate cure?

Unlike some adhesives that cure by evaporation, or heat, cyanoacrylate owes its special instant curing process to the presence of moisture, which reacts instantly on exposure to air, providing there is even just a small amount of relative humidity in the atmosphere.

Is Cyanoacrylate Super Glue?

No, but Super Glue is cyanoacrylate. Certain types of Cyanoacrylate are referred to by the generic term super glue, as it identifies instant and strong-bonding properties that people know. Super Glue is also a registered trade name of a specific type of cyanoacrylate. Loctite popularized the Super Glue brand under distribution rights from the original patent holder Eastman Kodak.

How long is the shelf life of cyanoacrylate?

A maximum of 12 months if unopened, and around 4 to 8 weeks if opened. This will vary with a product type, manufacturing and storage environments; however, these figures are a good guideline for most cyanoacrylate products.

How do I extend the shelf life of cyanoacrylate?

Refrigerate unopened bottles, and then keep opened bottles securely capped at room temperature. Unopened bottles maintain their properties best when refrigerated. Once opened, do not refrigerate, as the moisture content will condense and prematurely cure the adhesive. Store containers at room temperature, around 50-70 degrees Fahrenheit.

To prolong the shelf life of opened bottles, make sure the nozzle is clean and securely sealed, an then tighten the cap or replace the pin to ensure the glue is air-tight. Storing in an air-tight outer container with silica gel to remove any internal moisture will also prolong shelf life.

What is the average cure time of cyanoacrylate?

From 5 up to 90 seconds for a fixture, and from 8 to 24 hours for full curing. The cure time will depend on the surfaces engaged and primarily their moisture absorption qualities, as well as the type of cyanoacrylate used. We think of super glue as a super-fast curing glue, but there are fast and even faster types of cyanoacrylate. Surface insensitive types, for example, are super-fast curing, toughened types, and hybrid epoxies are slightly slower curing.

What is fixture time versus cure time?

Fixture time is the time before handling an application is possible, and full cure time is the time to reach full strength. Fixture time is curing to partial strength where light handling can be done. Cyanoacrylate adhesives gain most of their strength very quickly, but the remaining strength takes quite a bit longer. In lab terms, fixture time is the ability of an adhesive to handle a 3kg shear load.

In super glue's famous car lifting-within seconds demonstration, the glue is showing its best feature, tensile strength, from only fixture time. The full strength will be gained within 8 to 24 hours, depending on the type. Although an item can be handled after the fixture time, wherever possible, it should be left for the full cure time to gain full strength.

Why does superglue stick to almost everything?

Because of the moisture-curing process. Cyanoacrylate adhesives cure when exposed to moisture, and since there is moisture almost everywhere, they react well on almost every surface. Even for difficult surfaces, for example, those that repel water, there are modified cyanoacrylates, (see surface insensitive cyanoacrylate and cyanoacrylate gel below).

How do I prepare surfaces for application of cyanoacrylate adhesive?

Ensure surfaces are clean and dry. Remove all dirt, dust, oil (apply a solvent or primer if needed for this), and ensure surfaces are dry.

Can I glue porous surfaces like paper or leather?

Yes, use cyanoacrylate gel. Cyanoacrylate gel adhesives work best for porous surfaces since they fill the small gaps between the surfaces far better. The Infinity Bond Surface Insensitive Cyanoacrylate is good for these applications.

Can I use cyanoacrylate on flexible surfaces and rubber?

Yes, use a flexible type. Flexible glues are available with rubber additives for applications where movement may affect the joint. For active environments that require a flexible bond, we recommend the Infinity Bond Rubber Toughened Cyanoacrylate.

Does cyanoacrylate produce an exothermic reaction with natural materials?

Yes, there can be extreme heat produced when it reacts with cotton, wool, and sometimes leather. Heat and occasionally even smoke and fire can be produced when cyanoacrylate adhesives come into contact with natural fibers, particularly cotton and wool. It's recommended not to use cotton or wool gloves when handling the glue, as this can result in severe skin burns. Leather can also have an exothermic reaction. However, the mass of the leather somewhat dampens the effect. Leather is approved for use with cyanoacrylate glues.

How do I separate my instantly bonded fingers?

Painfully! Superglue loves the moisture content in our skin, so much so you might find yourself or your work attached to another finger instead of glued to your target. A pen or pencil point forced between the bond can help, as super glue weakens with shear loads (a ton can be lifted horizontally but putting the same joint under side loads it will break easily). If this doesn't work, acetone is one of the best home-based solvents for cyanoacrylate.

How do I remove super glue from surfaces?

With a solvent, a special cyanoacrylate remover, or prolonged soaking. Cyanoacrylate is a plastic when cured, and dissolves with the application of strong solvents, such as acetone, or special purpose cyanoacrylate removers can be purchased if cleaning is frequently needed. Care should be taken when applying solvents to plastic, as the solvent can eat away at the base material in the same way it removes the glue. In this case, it may be better to attempt prolonged soaking with soap and water (several hours), which takes quite a bit more time but will eventually soften the glue, and it will come off easier.

What is surface insensitive cyanoacrylate?

Insensitive cyanoacrylates provide better bonding for difficult surfaces and conditions. Cyanoacrylate is acid stabilized, that is it reacts badly to acidic surfaces, like paper and leather for example. It requires a weak base and moisture, meaning excessively dry areas can lead to problems. Super glue also bonds badly on glass due to the curing process.

A surface insensitive cyanoacrylate is specially formulated to react quicker and in more extreme situations, on active and inactive surfaces, and in very dry climates, with paper, glass or leather substrates.

Note that although a surface insensitive super glue will work for obscure substances, and if quick bonding is necessary, this is your best choice, and there are alternative epoxy-based resins that work better for leather, and silicone adhesives that work well on glass. Craft pastes like PVA are usually your best choice for paper.

Are there two-part cyanoacrylates?

Yes, they are hybrid cyanoacrylates which are two-part. The Loctite Cyanoacrylate Epoxy Hybrid Structural Adhesive is one example of a two-part cyanoacrylate epoxy hybrid, and Loctite Two Part Gel is a urethane cyanoacrylate. The combination provides the high strength of cyanoacrylate with the good structural strength and elasticity of other adhesives. While a cyanoacrylate does well under direct tension, it is brittle and weak under shear force, while epoxies provide better elasticity and shear strength.

Hybrid cyanoacrylates also provide gap filling qualities and easier bonding of rough surfaces that lower viscosity straight cyanoacrylates don't provide. The curing times will be slightly longer.

What is high, medium, and low viscosity?

It is the degree of fluidity of the adhesive in its non-cured state. A highly viscous fluid will not “run,” think joint grease, molasses or whipped cream, a low viscosity fluid is very liquid — think oil lubricants or water. Most cyanoacrylates are very fluid (low viscosity), which is fine when the surface is level and flat, or for small cavities. For porous surfaces or surfaces that are not level a high viscosity type, a gel is needed.

In most applications, we may use a medium viscosity type which keeps the adhesive where we put and but does not runoff. If we are joining tight fitted parts for example “Loctite-ing” (lock-tight-ing) a small screw in place, the function that Loctite is famous for, or for intricate modeling applications, we need a very low viscosity product.

What is cyanoacrylate gel?

Cyanoacrylate gel is a very high viscosity product that adheres well to porous surfaces. Most basic cyanoacrylates have a very low viscosity, which can make handling difficult. Trying to adhere a low viscosity product to a rough surface or a vertical wall, for example, is like trying to fill a cream cake with liquid cream. The product often runs off. Gel forms of cyanoacrylate provide the ability to adhere to surfaces where resistance against gravity is needed or where the glue needs to fill surface gaps.

What is Low Bloom Cyanoacrylate?

Low Bloom cyanoacrylate has less tendency for vaporization which causes blooming (a whitish or rainbow-colored residue around the joint). Blooming occurs when un-reacted cyanoacrylate particles (monomers) evaporate, then once airborne, react with surrounding moisture and fall back down in areas surrounding the joint. This leaves a whitish residue, which is not aesthetically pleasing in some cases, although does not affect the bond in any significant way.

The whitish residues can also be found in areas which are handled regularly by users. In applications where blooming is considered detrimental to the finish, a low bloom cyanoacrylate should be used.

As a fun fact, the blooming property of cyanoacrylate is used in crime labs successfully as latent fingerprint detectors for non-porous surfaces. The white residue created from the reaction of airborne particles of cyanoacrylate and moisture, adhere to latent fingerprints, exposing them under lab conditions.

Aside from using a low blooming adhesive, other ways to reduce blooming are by increasing airflow (carrying residue away from the joint), reduce glue areas exposed to air outside the joint (overflows), ensure temperatures and humidity are controlled to midranges and speed up curing times.

What is toughened cyanoacrylate?

A cyanoacrylate that is toughened by an additive, typically rubber to increase shear strength. Cyanoacrylate's weakest point is in shear strength. Adding toughening agents with elastic properties, such as rubber or anhydride, help toughen basic cyanoacrylate formulas for higher-strength applications, particularly for improved shear strength. Toughened cyanoacrylates take slightly longer to cure than normal super glues and may need an accelerator if fast cure times are needed.

At what temperatures can cyanoacrylate be used?

Most up to 200 degrees Fahrenheit, special applications up to 275 degrees Fahrenheit. If using cyanoacrylate in special purpose applications such as extreme heat, there are special high heat types of cyanoacrylate that are designed to withstand higher heat and cyclic heat.

What is “flashcure?”

Quicker curing capability under certain light wavelengths. A flashcure cyanoacrylate adhesive does exactly what it sounds like, it cures at extremely fast rates, within seconds, when exposed to certain lights, typically UV or visual forms. Many flashcure applications also have fluorescent visibility under UV light to check bonding.

When should a primer be used with cyanoacrylate adhesives?

When dealing with inactive surfaces, and in consultation with guidance material. A primer can be used to help bond on inactive surfaces. A primer helps flash off substrates and prepares the surfaces for better adhesion. Primers may not work on all surfaces, which is why it's important to consult manufacturer's guides.

When should an accelerator be used with cyanoacrylate adhesives?

When increasing cure speed or gap-filling is needed, especially in cold, dry conditions. A special-purpose accelerator can be used to speed up the curing time where very quick bonding is needed or in very cold or dry conditions.

Can cyanoacrylate be used in medical applications?

Yes, certain types of cyanoacrylate are FDA approved for medical use. Cyanoacrylates moisture curing properties led to its early popularity in medical use, where tissue-based moisture is ineffective against the curing process, and in fact assists it. First used in veterinary applications, and for emergency first aid for military, it now has widespread use as a medical adhesive.

Medical grade cyanoacrylate topical skin adhesive is used effectively for closing wounds, termed liquid bandaging. It is also widely used in orthopedic and dental applications. New applications of cyanoacrylate in the medical industry are being discovered all the time, and one application involves lifesaving surgery for infants.

It's obviously important the correct grade of medical glue is used since the USP classifications range from I to VI, use in medical equipment is Classes IV to VI whereas full use in internal medical applications such as bandaging, or surgery are Class I products.

Still Have Questions?

If you have further questions about cyanoacrylate adhesives or would like to talk to a specialist about your specific application, contact us. One of our knowledgable team members would be happy to assist.